Now that I have a CNC machine, I need tooling. But I can’t go sticking any old drill bit into the chuck. Drill bits are designed to drill, or plunge axially (up and down). For most operations, CNC machines use end mills that cut laterally (side to side).

End mills have cutting surfaces called flutes. The most common end mills have two to four flutes. Generally, fewer flutes evacuate more chips from your material, keeping the bit cool. However, more flutes produce a finer edge finish. There are four basic flute types, each optimized for different materials and edge finish. Solid carbide or carbide tipped are ideal since they don’t dull as easily as HSS (high speed steel) end mills.

Default Bit

The CNC 3018 machine comes whit standard 10 pieces drill bits 0,1 mm, 20 degree, 3,175. Unfortunately these bits are only for engraving. So if you want to do more then engraving we highly recommend ordering some other CNC bit’s.

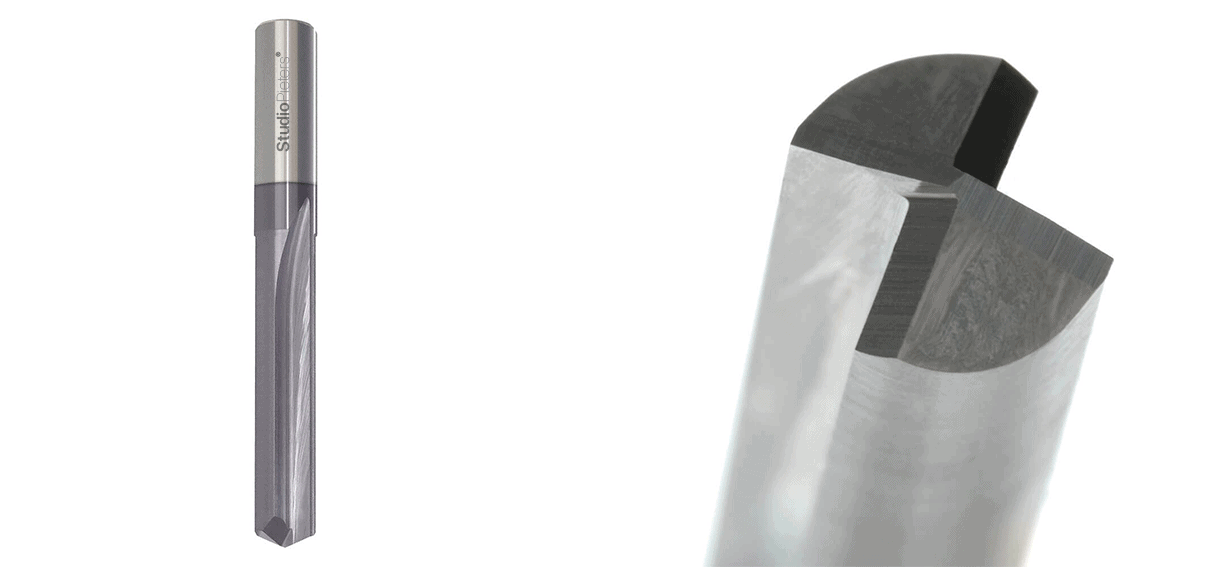

Straight Flute

These are best for general-use cutting with a good edge quality on many materials.

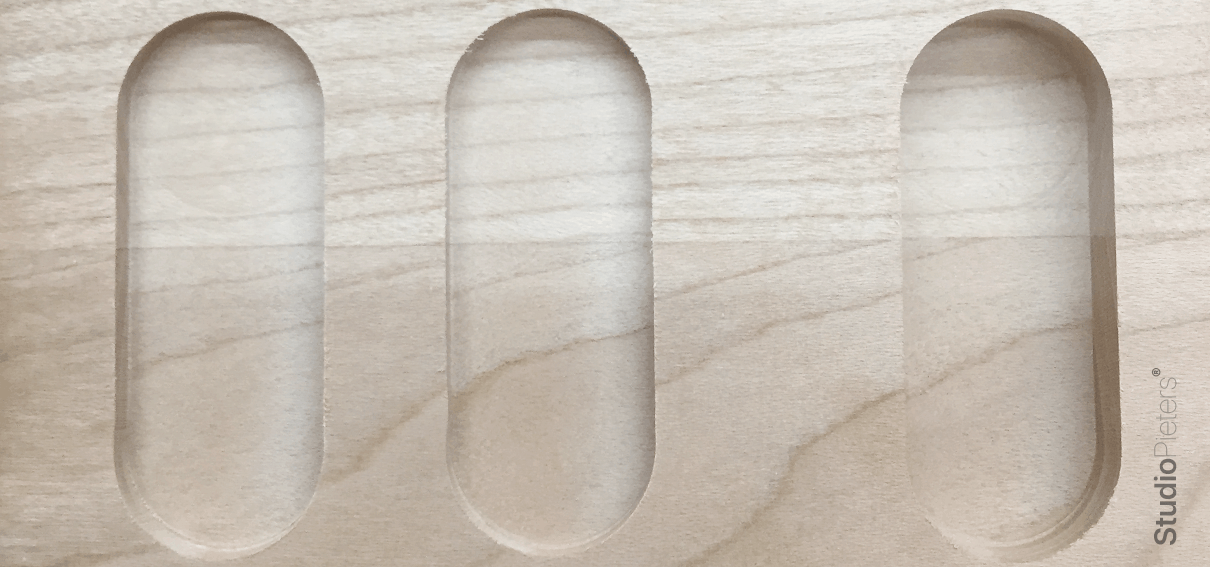

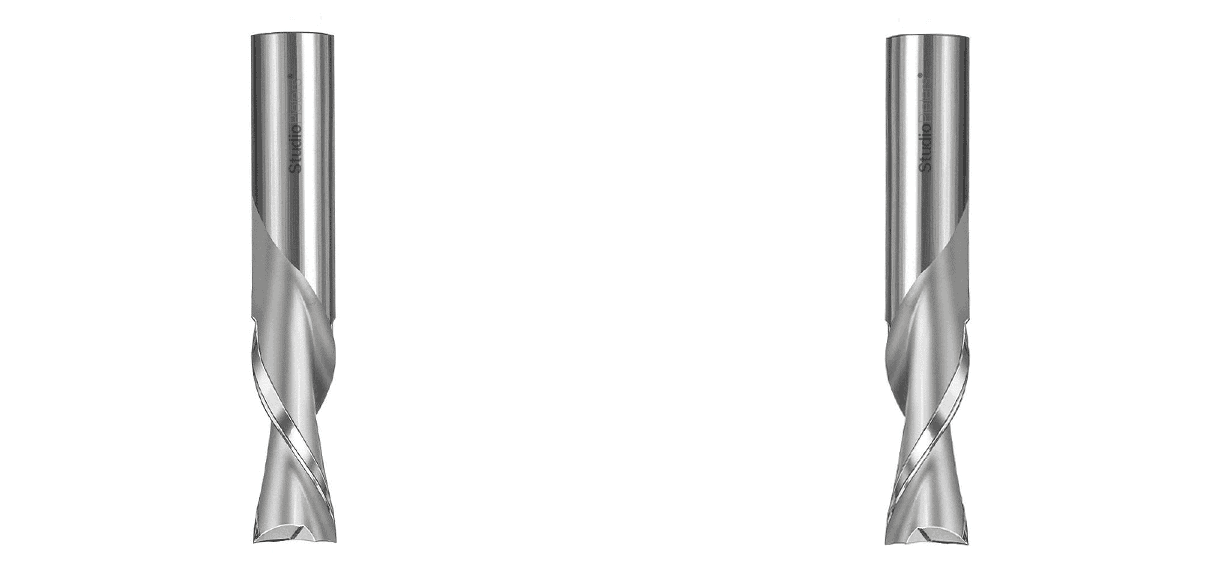

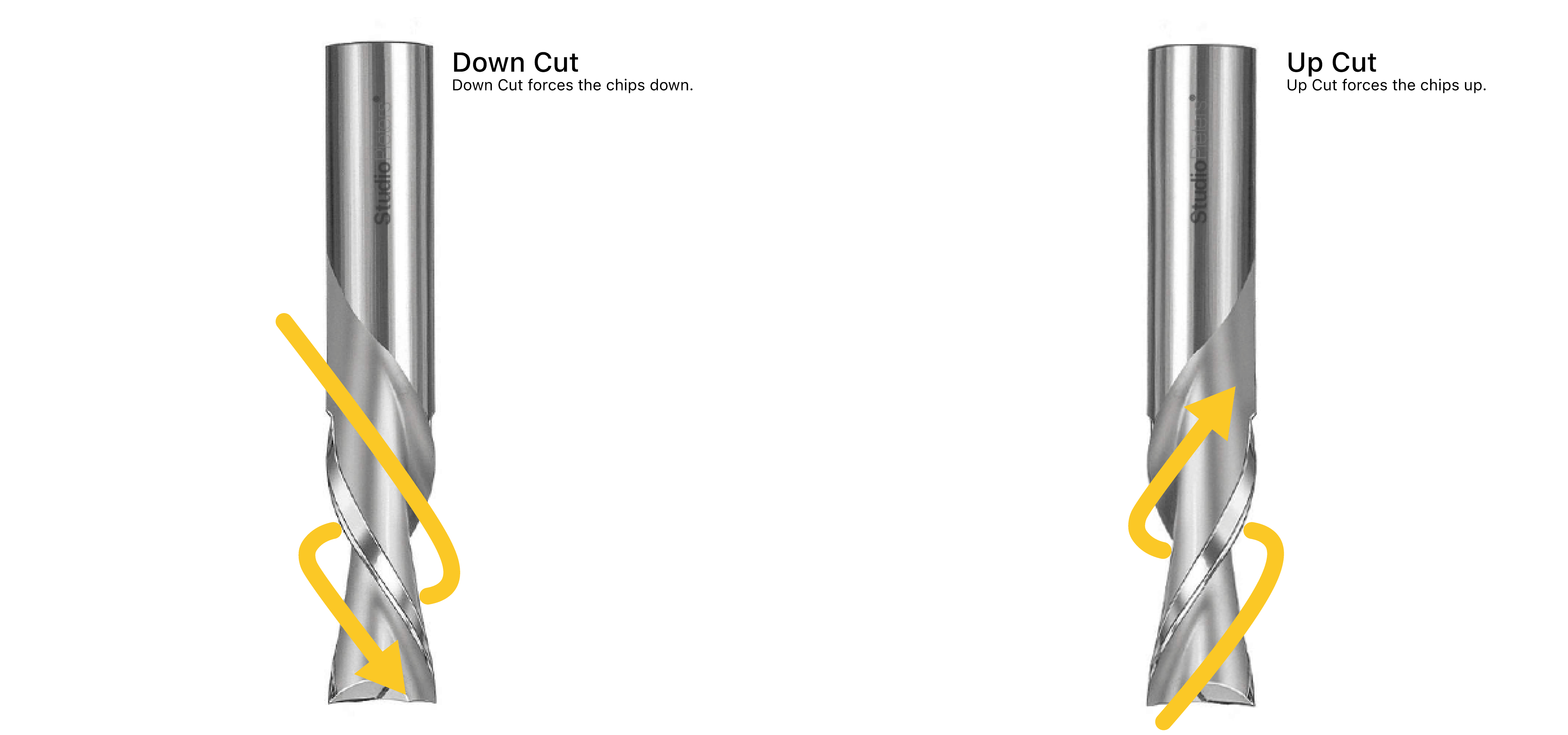

Upcut and Downcut End Mills

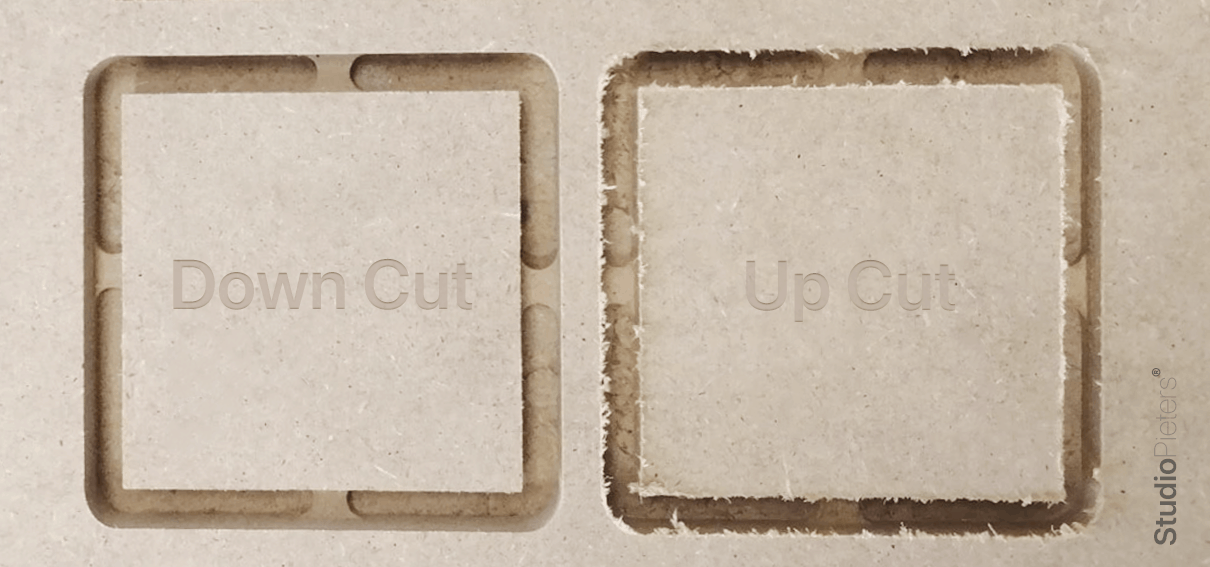

These spiral, flute-shaped end mills either carry chips up and away from the material or down into them. An upcut will keep the bit cool while quickly evacuating materials when cutting plastic or aluminum, however, it will fray the top surface, and may lift your material so be sure to have adequate hold-downs in place.

Downcut bits ensure a smooth top surface on laminates, assist with holding down your thin parts, and possibly avoiding tabs on larger parts. A single “O” flute is key for plastics like HDPE and acrylic when clearing materials. The flute helps avoid excess heat buildup, which may cause material to stick to and ruin the end mill and your part.

Compression

These bits combine the benefits of both upcut and downcut end mills, ensuring a smooth top and bottom face when cutting laminates and plywood at full depth passes, considerably reducing cut time.

Ballnose Mill

These bits have a rounded tip and are ideal for 3D tool paths. When combined with a “roughing” bit to clear large areas of material, this end mill will result in smooth 3D surfaces, especially with two or more passes.

V-Groove

A 60° or 90° V-bit is great for what’s called V-carving, in which the tip of a V-shaped bit is used to cut into narrow spaces, and the wide bottom is used to cut into larger spaces. V-bits can also create sharp corners that other end mills cannot because of their radiuses.

Table-Surfacing

These bits are used to surface your table quickly, giving a smooth and level work surface, ensuring accurate cut depths.

REFERENCE

Berytech Fab Lab ,Computer Controlled Machining(2021), CNC Machining is the process used in the manufacturing sector that involves the use of computers to control machine tools ,http://fabacademy.org/2021/labs/berytech/Computer_Controlled_Machining Make Community,6 Essential End Mills for Your CNC Machine(2021), Now that you have a CNC machine, you need tooling , https://makezine.com/2015/12/03/6-essential-end-mills-for-your-cnc-machine