CNC – 3018 Pro

Yes!, today I ordered my first CNC Machine. I had searched the internet for a affordable CNC router. An I found the CNC 3018 PRO. If you’re interested in making things, and since you’re reading this, we’re going to assume you are, you’ve almost certainly felt a desire to make plastic or metal parts. 3D printers are great, but have some drawbacks: limited material options, lack of precision, and long printing times. If you want plastic or metal parts that adhere to even moderately tight tolerances, a milling machine is your only practical option. There is, after all, a very good reason that they’re essential to manufacturing.

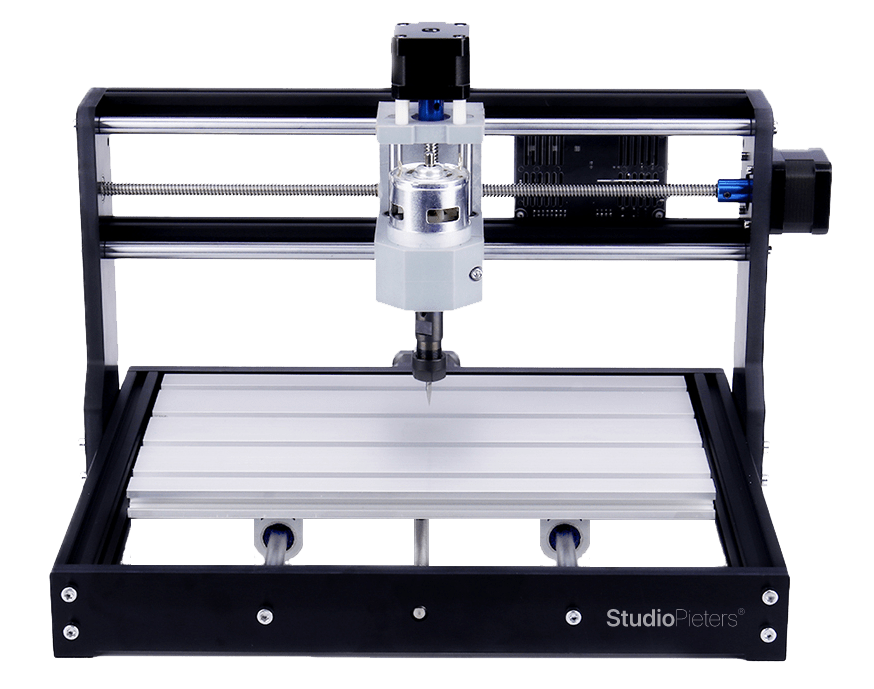

CNC 3018 PRO

Designed to deliver the best value and performance for any new Desktop CNC user. The CNC 3018 PRO is a great tool for getting started with CNC learning. If wood-working or DIY crafting is your hobby, you can use it to add features like curved words and exquisite patterns. If you are a student just learning CNC, it can help you engrave models that you can design with Autodesk fusion Cad software. which you are coding and designing. The CNC 3018 PRO is the perfect starter with the performance you need to work with REAL materials and get creating with Industry-leading Autodesk fusion Cad software right out of the box .

What Is a CNC

Nowadays, lots of hobby machines are operated through Computer Numerical Control (CNC). A CNC router or mill uses subtractive manufacturing; it’s similar to drilling but has the ability to cut horizontally as well as vertically. Since the machine can cut along various axes, it has the ability to make a huge array of shapes.

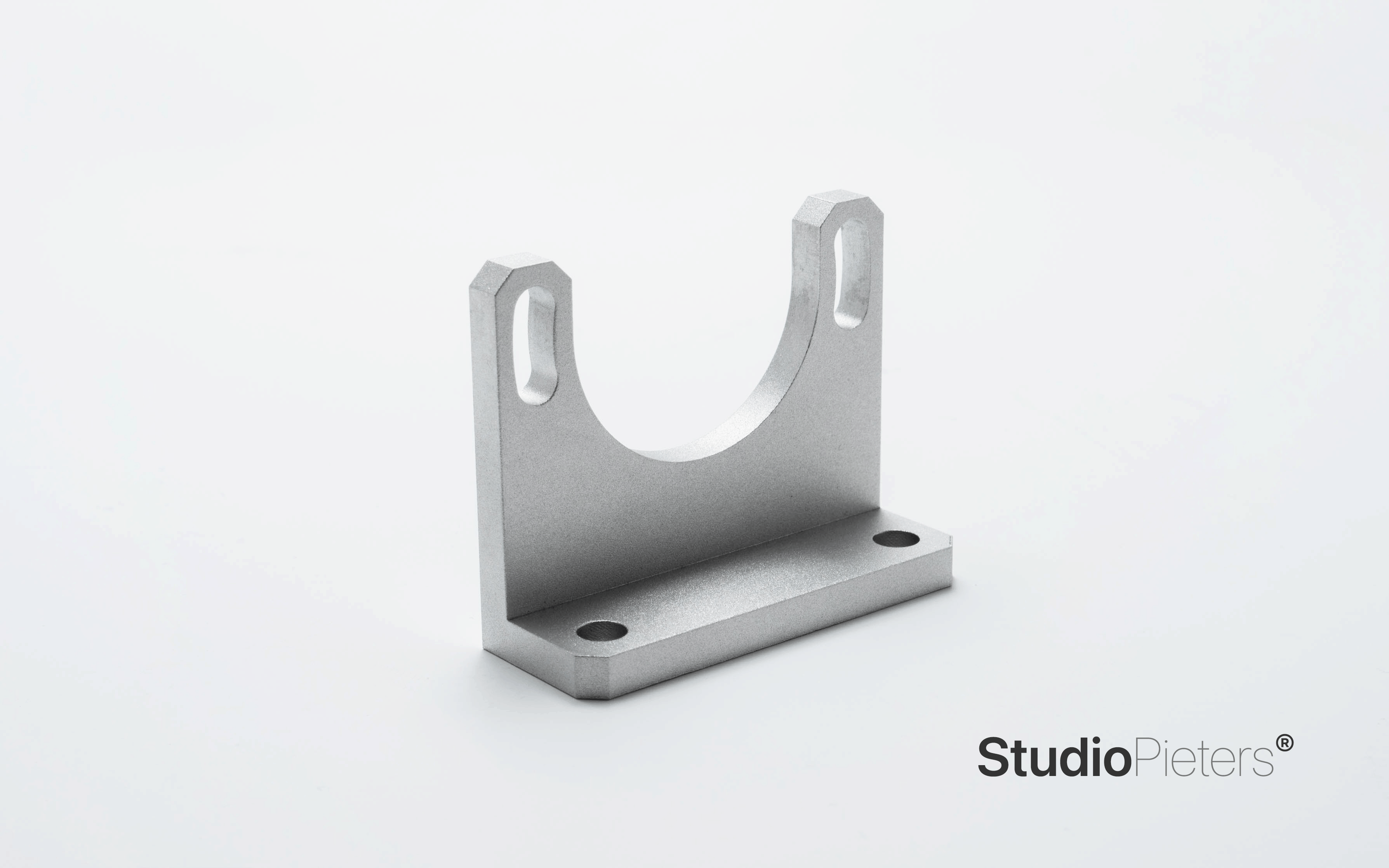

A particular reason one may use a CNC is to make a precision part made of one solid material. This material is usually soft, like wood or maybe aluminum if the machine is strong enough. Unlike 3D printing, which can result in structural weaknesses, machining in this way ensures a strong, whole part.

The CNC 3018 and CNC 3018 Pro

The CNC 3018 and CNC 3018 Pro are generic cnc machines. Similar to K40 laser cutters, there’s no one manufacturer or official design specifications for these machines.

Generally speaking, when a CNC has numbers in its model number, it’s a reference to the size. In the case of the CNC 3018 and CNC 3018 Pro, the dimensions are 300 x 180 mm. This is a good size for a desktop CNC and is primarily why there are more CNC 3018’s compared to other variants, like the CNC 2418 and the CNC 1610.

These machines can be used to cut anything from wax to wood, and working with them gives you an in-depth look at how CNC machines work on a mechanical level. If you’re wanting to get started with CNC engraving or milling, this is a great place to start!

Features

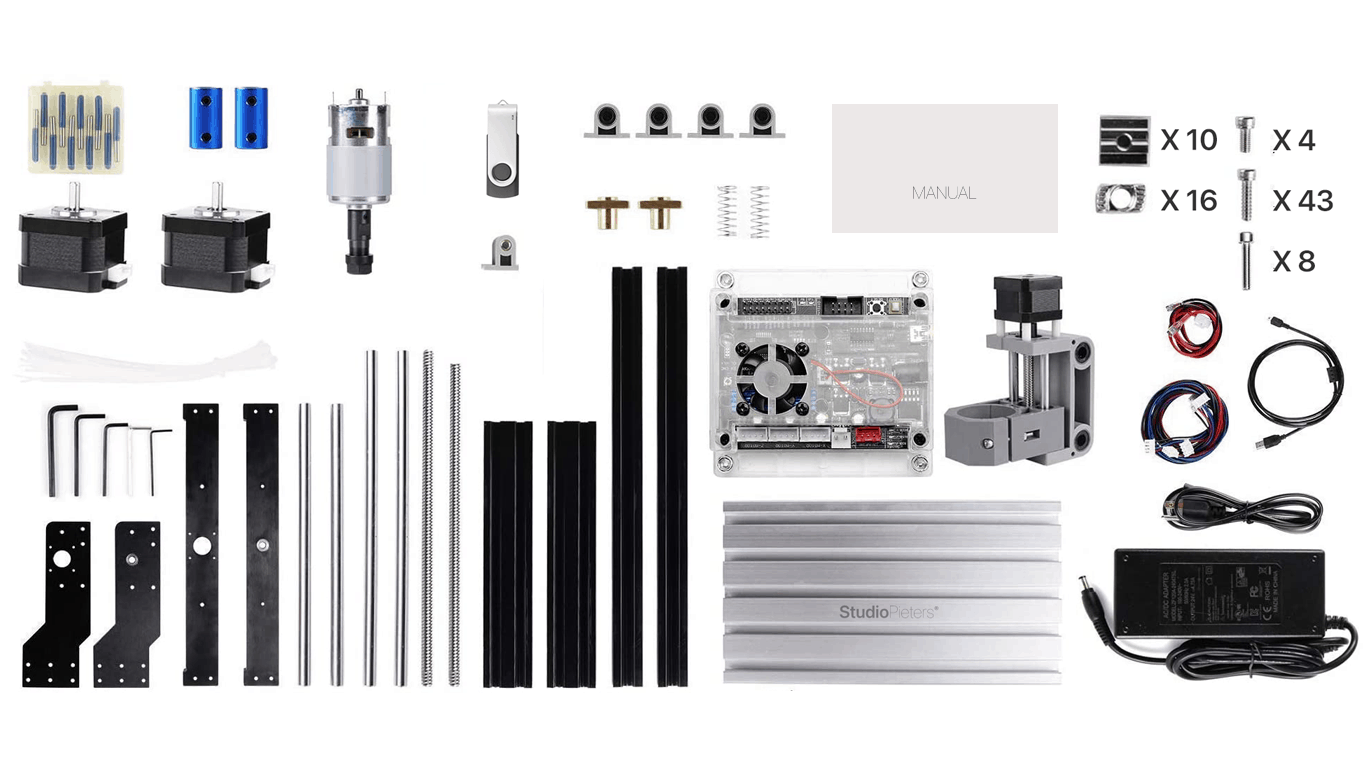

Most if not all CNC 3018’s require some assembly to get started, with the Pro version requiring less. Even though machine setup is relatively straightforward, some work and tinkering are required to get the machine running well. This includes the proper attachment of parts, learning the software, and a thorough inspection of the machine.

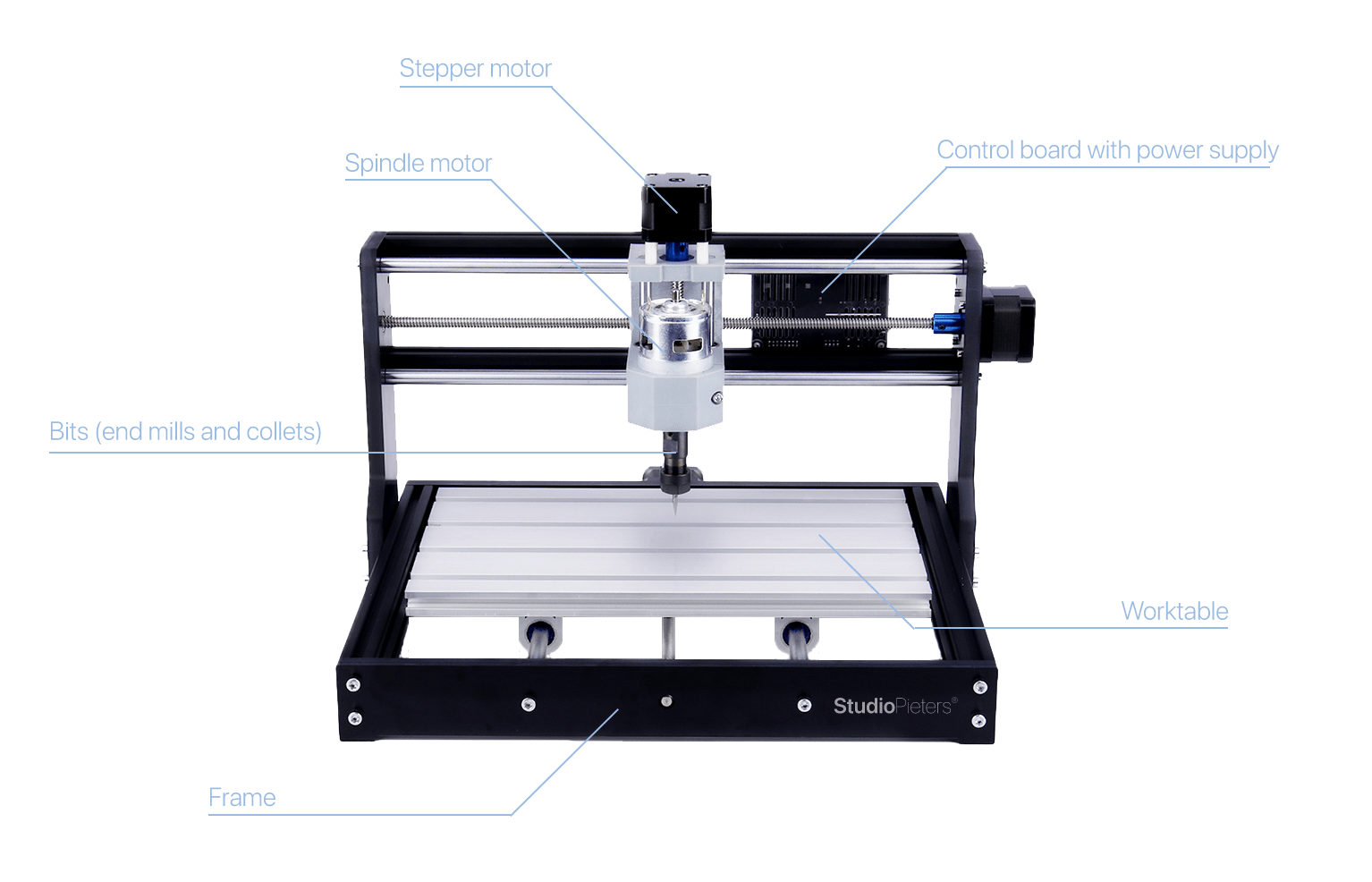

CNC machines all come with the same main components:

- Spindle motor

- Bits (end mills and collets)

- Control board with power supply

- Stepper motors

- Clamps

Every component plays an important role in the machining process. And as with most project-oriented tools, you can always upgrade various parts to achieve higher performance and quality.

When working with any autonomous machine, safety is important. First and foremost, this means supervising the machine while it’s working. However, installing an emergency shut-off switch or plugging the machine into an outlet controlled by a light switch is also highly recommended.

An In-Depth Look

Let’s dive a little deeper into what some of the above components are and do. Within the context of parts, it’s worthwhile mentioning that the main differences between stock and Pro models are the frame and some accessories.

Spindle motor

The spindle motor is what drives the machining process, as its speed and power determine what materials can be cut. The 3018 uses a 775 spindle motor with an ER11-style chuck. For this speed and power, it’s recommended not to engrave anything harder than brass or aluminum 6061. Anything harder can result in the motor burning out or some parts breaking.

Eend Mills & Collets

End mills are used to cut material. The type of end mill used determines the type of cut that is made. Three commonly-used end mills are ball, bull nose, and square, but there are several other types available. Make sure to research what type you need, especially considering what material it should be made from, how many flutes it should have, and what coating is best for your project.

Collets attach the bits to the spindle. The CNC 3018 and CNC 3018 Pro specifically use ER collets for ease of access. There are differently-sized collets for different diameter end mills, so always make sure the collet’s outer diameter fits the chuck attached to the spindle.

Control Board

The control board is the brain of the machine. Having a good board helps keep consistent results when cutting. The CNC 3018 has one that primarily uses GRBL, but other programs are also available.

Power Supply

The power supply is important. If the 775 spindle isn’t powerful enough for your needs, you’ll need to get a new motor. Depending on the new motor’s power, you may have to upgrade the power supply, too.

Coolant

CNC engravers don’t usually come with coolant, but it can be helpful when cutting certain metals and is required with others. This is usually only needed if you’ve upgraded the spindle motor.

Accessories

The CNC 3018 Pro also comes with a few extra drill bits, an SD card reader, and an ER11 collet with an extension rod.

Performance

For a budget machine, the CNC 3018 and CNC 3018 Pro version have the potential to do great work. To get the most out of the machine, it’s best to learn about engraving and milling, in general. This means researching spindles, end mills, speeds, and feed rates, which will prevent loss of time and money through accidental damage of bits, work material, and machine parts.

Once you learn the ins and outs of machining you should be able to cut material like brass and aluminum 6061. And if you upgrade the spindle, you can cut anything you want! (Within reason…)

Getting a CNC 3018 or CNC 3018 Pro is a great start to the machining craft. You’ll learn how a CNC router works both inside and outside the machine! When working on new projects, you can find a whole host of helpful resources on tools, parts, and general information.

Tuning

CNC machines don’t require many components to operate, but they do require a lot of preliminary work, most of which consists of proper assembly. It’s also best to learn introductory code so that you can make adjustments when doing probe commands. More in-depth research can be helpful for specific hiccups.

Upgrades

Upgrading allows you to accomplish more with the same machine. Just make sure to inform yourself well on how to properly replace parts and whether or not certain upgrades are dependent on others. Here’s what upgrading the following parts will do:

- Spindle: Upgrading the spindle means you can work with more materials. This will also require switching out the power supply and mounting equipment.

- Endstops: Many versions of the CNC 3018 or CNC 3018 Pro don’t come with endstops. Adding some aftermarket upgrades helps when doing probes and homing the machine.

- Collets: Getting collets with different internal diameters allows for differently-sized bits to be used. This allows for faster, more diverse, and higher quality work.

- End mills: Different types of end mills are required for different jobs. Finding the right one is the key to success.

- Drill Bits: Working on different materials requires differently-sized drills made of different materials in order to function properly.

- Chamfer bits: Always helpful, chamfer bits are used for cutting the edges or the outside of a material.

- Coolant: Adding a coolant spray helps with machining hard material like metals. The CNC 3018 or CNC 3018 Pro isn’t usually meant for this kind of work, though, unless you’re prepared to upgrade the spindle.

Specifications

There are a few different brands of CNC 3018’s out there. So specifications can vary. As mentioned above, the machine we’re referencing here is the SainSmart CNC Pro.

Building

- Working area: 300 x 180 x 45 mm (11.8″ x 7.1″ x 1.8″)

- Materials: Woods, Plastics, PVCs, soft aluminum (6061), brass, PCBs

- With upgrades: Depends on spindle speed and strength

Mechanical Specifications

- Motor: 775 motor, 24 V, 10,000 RPM

- Upgradeable: Yes (switchable to Laser Module)

- Machine dimensions: 330 x 400 x 240 mm (13.0″ x 15.7″ x 9.4″)

- Frame: Extruded Aluminum

- Linear system: Extruded aluminum linear rails with drive-thread

- Motion: Stepper motors

- Z-Prove: No

- Limit Switches: No

Software

- Programs: Grbl v1.1 / GrblControl (Candle)

- Interface Compatibility: Windows and Mac (Linux with use of a proxy)

Other

- Manufacturer: SainSmart

- Connectivity: USB

- Onboard controls: Yes

- Emergency shut-off: No (can be added aftermarket)

Where to Buy

There are a few reliable places to get a CNC 3018 or its upgraded Pro version. We recommend purchasing from a reputable seller that offers warranties and easy replacements. Some retailers even have technical support available!

I bought Mine at Aliexpress You can use the buy Botton below, this is a affiliate link, more information about affiliate links can be found here!

REFERENCE

All3DP, The CNC 3018 (Pro) Buyer’s Guide (2020), Nowadays, lots of hobby machines are operated through computer numerical control (CNC), https://all3dp.com/2/cnc-3018-pro-buyer-s-guide/ SainSmart ,CNC Router 1810-PRO DIY Kit (2020), affordable CNC Router Kit, the 1810-PRO boasts the same outstanding performance as the 3018, in a compact and affordable package., https://www.sainsmart.com/collections/cnc-machines/products/sainsmart-genmitsu-cnc-router-1810-pro-diy-kit